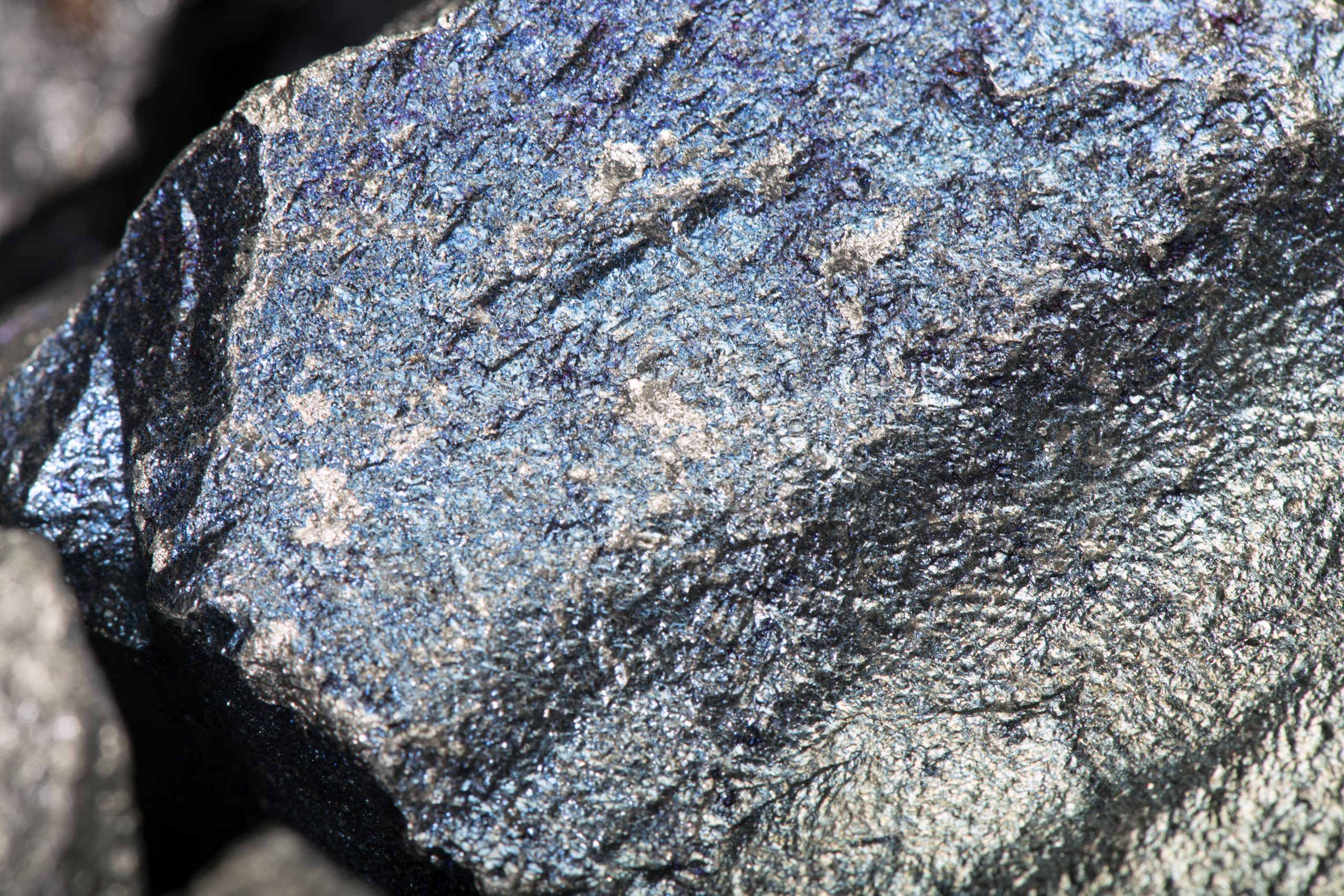

What is medium carbon ferromanganese?

This ferromanganese ferroalloy belongs to the category of ferromanganese, which are classified based on the amount of carbon, in average ferromanganese, its carbon should be a maximum of two percent. They are made of silica, phosphorus and sulfur. Medium carbon ferromanganese is an essential deoxidizer and desulfurizer in the steel industry. Quality steel needs deoxidization and desulfurization in the smelting process, and the use of deoxidizers greatly increases the cost. Therefore ferromanganese is a cheap oxidizer. Desulfurization is to separate sulfur and other harmful substances in steel, so ferromanganese can achieve the purpose of desulfurization, effectively reduce the content of harmful elements in steel and improve the quality of steel. In the steel industry, about 3 to 5 kg of 75% manganese is consumed per ton of steel produced.

Medium carbon ferromanganese applications

Due to the characteristics of medium-carbon ferromanganese, it is widely used in the casting industry, in the iron and steel industry, and in steelmaking. Ferromanganese is an oxidizing material and an alloy widely used in steelmaking. The density of manganese is 7.43 grams per cubic centimeter, the melting point is 1245 degrees Celsius and the boiling point is 2150. Medium carbon ferromanganese as an alloying additive, iron can improve the hardness, ductility, toughness and wear resistance of steel. Widely used in structural steel, tool steel, heat-resistant steel, wear-resistant steel. By adding ferromanganese to the melt, it makes steel and cast iron easy to turn, which feature is widely used in car parts or parts that need turning.

Characteristics of ferromanganese medium carbon

Manganese is obtained from manganese ore in the form of ferromanganese, and ferromanganese is used in steelmaking to provide oxygen, neutralize the negative effect of hot sulfur during hot rolling, increase the depth of hardness and increase resistance to wear, tensile steel, and replace nickel metal in stainless steels. is used The main factor for hot cracking of steel is the formation of an acetic compound (Fe-FeS) with a melting point of 988 degrees Celsius. By adding ferromanganese, this compound turns into MnS plastic with a melting point of 1650 degrees Celsius.

Element | Manganese (Mn) | Carbon (C) | Phosphorus (P) | Sulfur (S) | Silicon (Si) |

|---|---|---|---|---|---|

Percent | 75-80 | Max 2.0 | Max 0.2 | Max 0.02 | Max 2.0 |