What is low carbon ferrochrome?

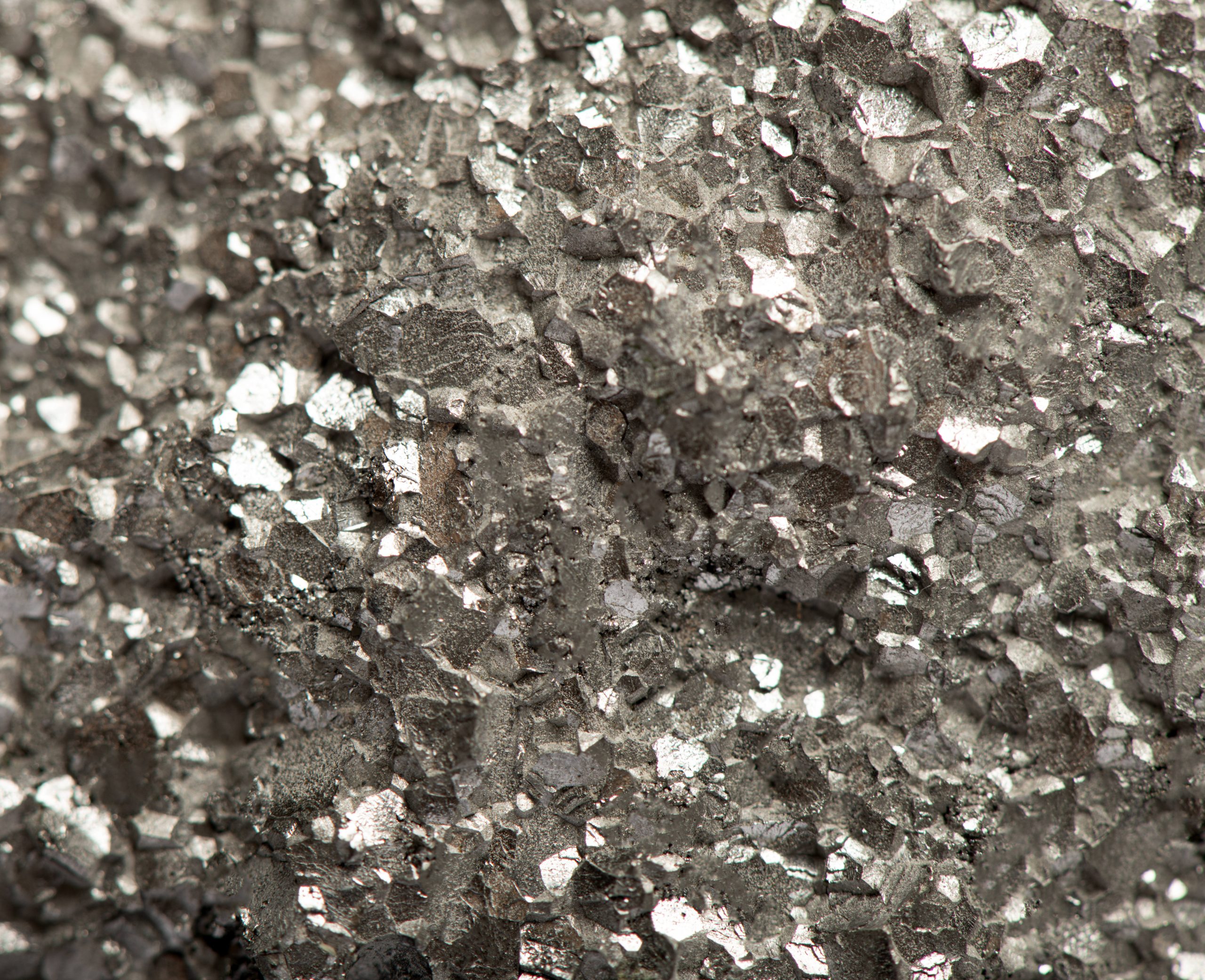

Low Carbon Ferro Chrome, which is known by the abbreviation LcFeCr, belongs to the family of ferroalloys and is obtained from the combination of chromium and iron. The composition of this composition consists of chromium, which is generally up to 70%. The rest of the elements that make up this composition are small amounts of silicon, carbon, phosphorus and sulfur. In this composition, after chromium, the most important element is its carbon content, which should be at most 0.3%. Ferrochrome has a gray and silver appearance and is generally granulated in the form of lumps and powders. The most consumption of ferrochrome in casting industries is precisely used in stainless steel, and it is one of the most diverse and widely used alloy elements in steel. Also, this ferroalloy is used in powdered form in the production of welding electrodes. Some of the properties of ferrochrome provide resistance to corrosion and oxidation in the alloy. It is a material with hardening properties, it improves wear resistance. It also maintains strength at high temperatures. Chromium is an irreplaceable element in all stainless steels. Apart from making stainless steel, it is also used in making acid resistant steels.

Applications of low carbon ferrochrome

The most common use of ferrochrome can be seen in the production of stainless steels. Because the chromium present in these steels makes them resistant to corrosion and their polished color is usually due to the presence of chromium.

High carbon ferrochrome is used in the manufacture of tool steel bearings and other alloy steels.

Low-carbon ferrochrome is used in the production of stainless steel and acid-resistant steels.

A type of ferrochrome is also used in the production of cast iron.

It is used in powder form in the field of powder metallurgy.

Ferrochrome is also used in the production of lingosulfonate, which is used in water systems.

Fine particles of ferrochrome are also used in leather industries.

Properties of low carbon ferrochrome

Ferrochrome alloy is found in solid form and in different forms such as small crystals, lumps of powder or granules and has a variable color between metallic gray and light gray. This odorless alloy does not dissolve in water and has flammable particles. It is stable in normal environments with certain temperature and pressure conditions. Chromium can increase the hardness of steel and cause the homogeneity of this property. Chrome also improves the thermal resistance of steel; And it is resistant to corrosive agents at room temperature. Chromium’s melting point is above 1500 and its boiling point is between 2700 and 3000 degrees Celsius. The density of ferrochrome ranges from 6 to 9 grams per cubic centimeter and varies depending on its composition.

Element | Chrome (Cr) | Silicon (Si) | Carbon (C) | Phosphor (P) | Sulfur (S) |

|---|---|---|---|---|---|

Percent | 65-70 | Max 1.0 | Max 0.1 | Max 0.04 | Max 0.03 |